Machining is one of our strongest businesses and can produce the greatest cost savings for customers. Machining generally has a longer cycle time and requires better control to ensure consistent quality, thus requiring more labor and effort.

After determining the content of a processing procedure, it is necessary to make a detailed processing procedure plan, that is to arrange the processing order of the content and consider the tool trajectory design when programming. One job step is usually programmed to be one processing procedure. The step sequence actually is the implementation order of processing procedures.

Generally, CNC milling concentrates the working procedures (CNC milling adopts concentrated procedures to process CNC milling parts). At this time, job step can be conducted according to general order arrangement of cutting. According to the processing principle, we machine CNC milling parts from the simple procedure to the complex. When arrange the order of CNC milling processing procedures, the following questions should be paid attention t

(1) The positioning and clamping of next procedures should not be influenced by the former processing procedure. The interspersed universal machining processes should also have been considered.

(2) First process cavity, then process Profile

(3) The process with same positioning, clamping or the same cutting tool should be carried out continuously to reduce the times of repeated positioning.

(4) If there are several processing procedures in one installation, we should first arrange the processing procedure which has less destruction to the rigidity of workpiece.

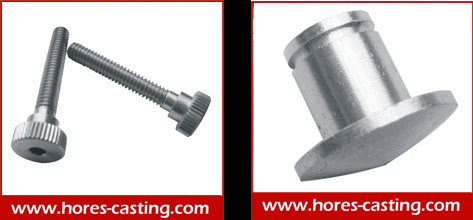

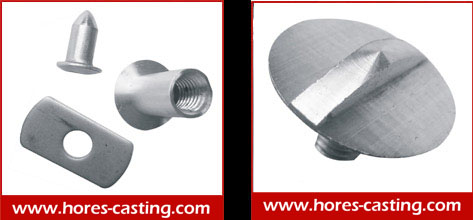

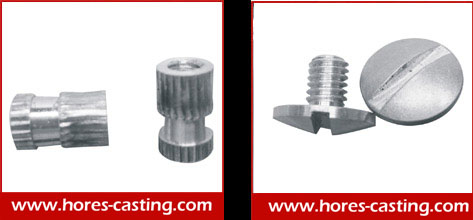

As a professional supplier of machining parts manufacturer in China, we can provide various kinds of CNC milling parts

|

Materials: |

High-grade and stainless steel alloys according to DIN, EN, ISO, ASTM, BS, JCSI. |

|

Weight per piece: |

1 g to 1.000 kg. |

|

Dimensions: |

?2 to ?800 mm. |

|

Tolerances: |

According to DIN ISO 2768 or DIN 7168. |

|

Quantities: |

Medium and large series. |

|

Surface treatment: |

Hot-dip galvanising, galvanising, Cr6 free coating, glass balls and shot blasting, priming, electro-polishing, tumbling, burnishing, pickling, passivating, lacquer finishing. |

|

Checking equipment: |

Chemical analysis by spectrometer, mechanical properties for tensile strength, yield stress, nothced bar impact testing, X-ray, pressure testing up to 200 bar, 3-D co-ordinate CNC measuring machine, metallography. |

|

Quality System: |

EN/ISO 9001:2000 - ISO/TS 16949:2002 |

|