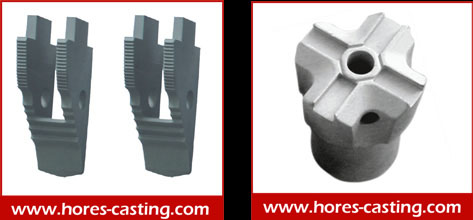

If you have ever wondered which process you can use to achieve a design exhibiting cavities, containing many corrugations or also including undercuts, the answer is investing casting .

Even the most complex parts can be produced "from one casting". With special steel materials that are difficult to machine in particular, precision casting offers significant economic advantages. However, the potential to produce complex parts is only advisable if there is corresponding quality in the end result. And it is precisely here that the capabilities of precision casting become clear. High dimensional accuracy, adherence to close tolerances (approx. +/- 0.5% from the nominal size), exact contours and perfect surfaces.

We have two major processe:

-lost wax process: use silical gel (for small tolerances, fine surface).

-water glass process: use water glass (for big tolerance, rough surface).

|

Materials: |

|

Stainless Steel |

Alloy Steel & Carbon Steel |

Other |

|

CA-15 |

CF-8M |

A732 |

A356 |

HK-40 |

|

CA-40 |

CF-8C |

A27 |

A487 |

HK-30 |

|

CF-3 |

CA-6M |

A216 |

A352 |

HC |

|

CF-8 |

316 |

A486 |

|

HH |

|

316L |

304 |

A643 |

|

HP |

|

303 |

410 |

|

|

|

lost wax process

Steel, high-grade and stainless steel alloys according to DIN, EN, ISO, ASTM, BS, JCSI.

Special materials based on Cobalt and Nickel, aluminium alloys.

|

|

Weight per piece: |

Steel, high-grade and stainless steel materials 0.005 to 50,00 kg.

Aluminium alloys 0.005 to 20,00 kg.

|

|

Dimensions: |

Max. 500 x 500 x 500 mm. |

|

Tolerances: |

According to VDG P690 (about ¡À 0,7 % of the nominal dimension).

ISO 8062 |

|

Quantities: |

Small, medium, and large series. |

|

Machining equipment: |

All current processing methods, CNC and conventional machining. |

|

Surface treatment: |

glass balls and shot blasting, priming, hand Polishing ,electro-polishing, tumbling, burnishing, pickling, passivating, zinc coating. |

|

Checking equipment: |

spectrometer, mechanical properties for tensile strength, yield stress, notched bar impact testing, X-ray, pressure testing up to 200 bar, 3-D co-ordinate CNC measuring machine, metallography, magnetic particle flaw inspection. |

|

Quality System: |

EN/ISO 9001:2000 |

|